In the previous post, I argued that many people unknowingly subscribe to a defunct management philosophy: that you can improve the overall performance of a system (such as a company) by individually improving the performance of its parts.

These isolated improvements are known as “local optima.” A local optimum is whatever is best for the performance of one individual part, whereas the global optimum is what is best for the performance of the system as a whole.

To put our previous conclusion a different way: adding up a series of local optima does not automatically lead to a global optimum. In fact, it can lead to the exact opposite.

This is perhaps the most counterintuitive aspect of complex systems: that individually optimizing the performance of each part results in an overall system that is severely under-optimized. The more you “improve” each part of a system, the worse overall performance gets.

Let’s take a look at how this manifests in companies.

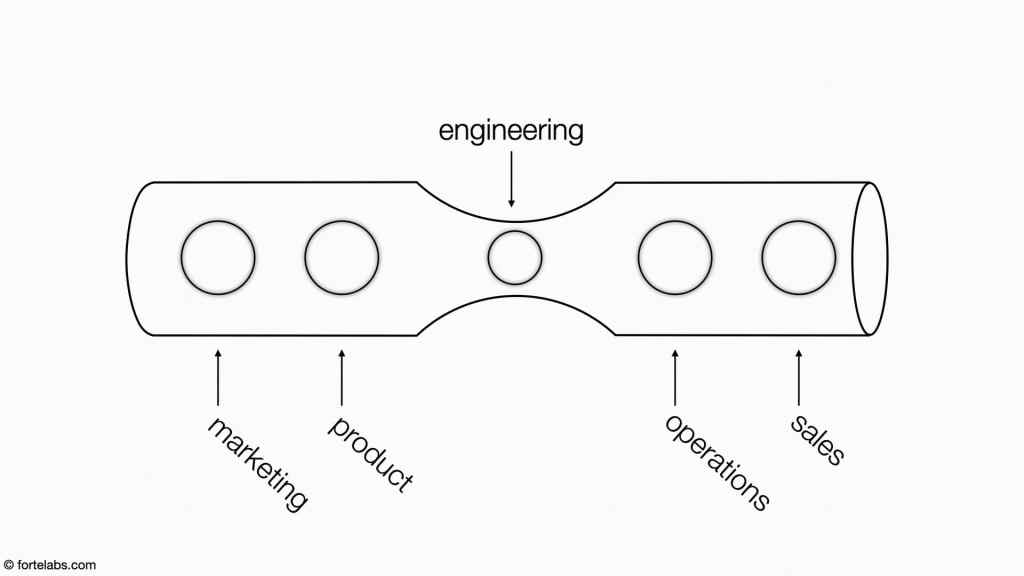

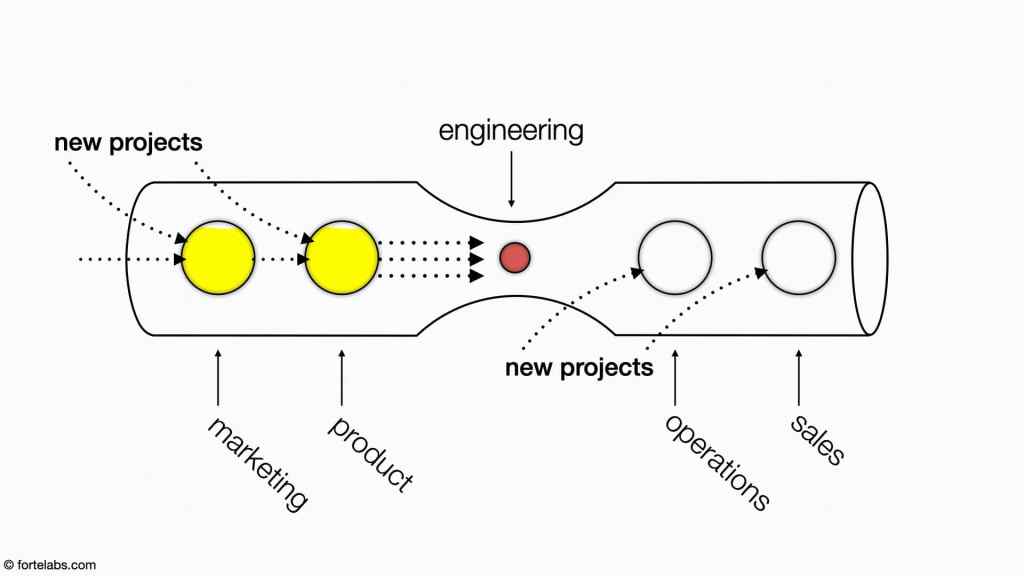

Imagine every department in a business as a section of pipe, with pieces of work (such as reports, documents, charts, slide decks, emails, and decisions) flowing from the left to the right. Each circle represents a certain department’s individual capacity.

Now let’s say that the Engineering department is the bottleneck of the organization, with the lowest number of staff people and thus the smallest capacity:

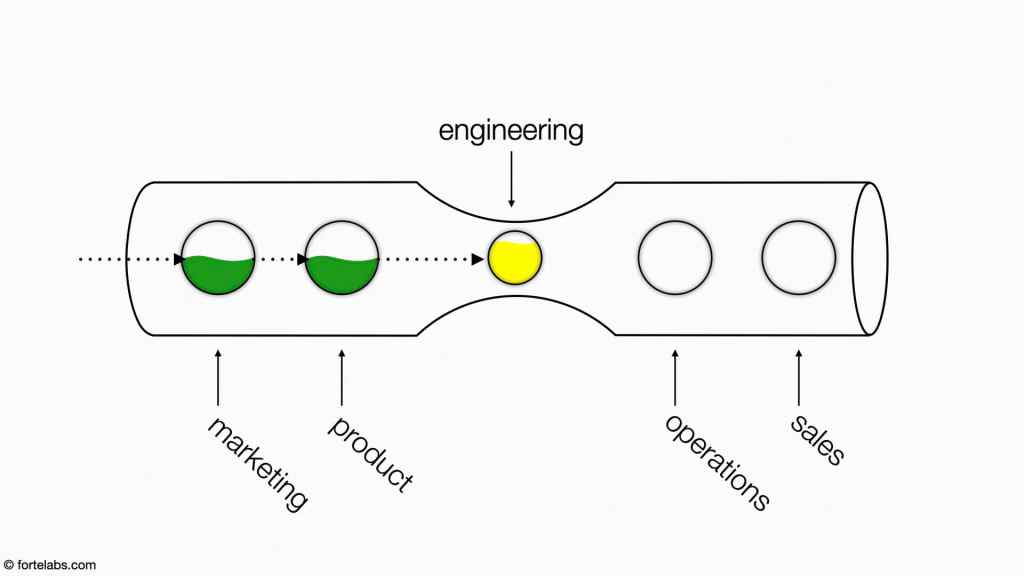

Sales closes a deal and hands it over to Product. Product scopes the project and passes it to Design to make some wireframes. Design sends their work to Engineering to actually build it. Everyone feels productive and happy.

But here’s where things start to get interesting. Engineering’s capacity is filled very quickly, which means that sending any more work their way won’t result in any more finished product coming out the end.

But what are Sales, Product, and Design to do in the meantime? They can’t afford to wait around. They are operating under the universal rule of the modern workplace: “Stay busy.” Nothing strikes terror into the heart of a manager like an “underutilized resource.” And nothing strikes terror into the heart of an employee like the feeling that there may not be enough work to justify their employment.

So what do they do? They find new clients to pitch, new products to develop, and new designs to improve. We can always find something to do.

This might not seem like a problem. In fact, it may sound like I’m describing a high functioning organization full of responsible, hardworking people and not a lazy slacker in sight.

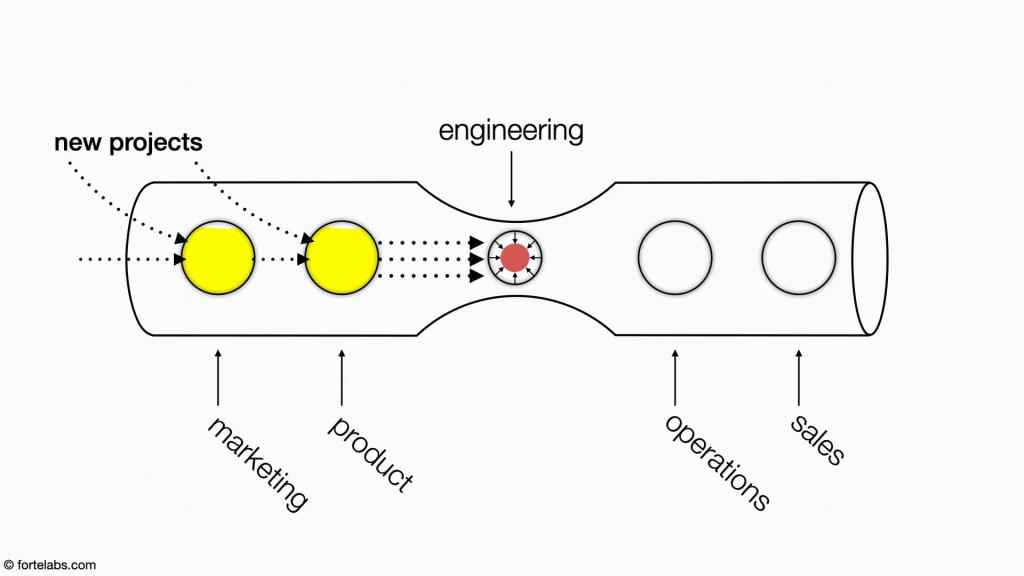

But there is a deeper principle at work. If we apply the principles we discussed previously, it soon becomes clear that we’ve discovered some local optima. The rule to “stay busy” is effectively optimizing for the performance of each individual department.

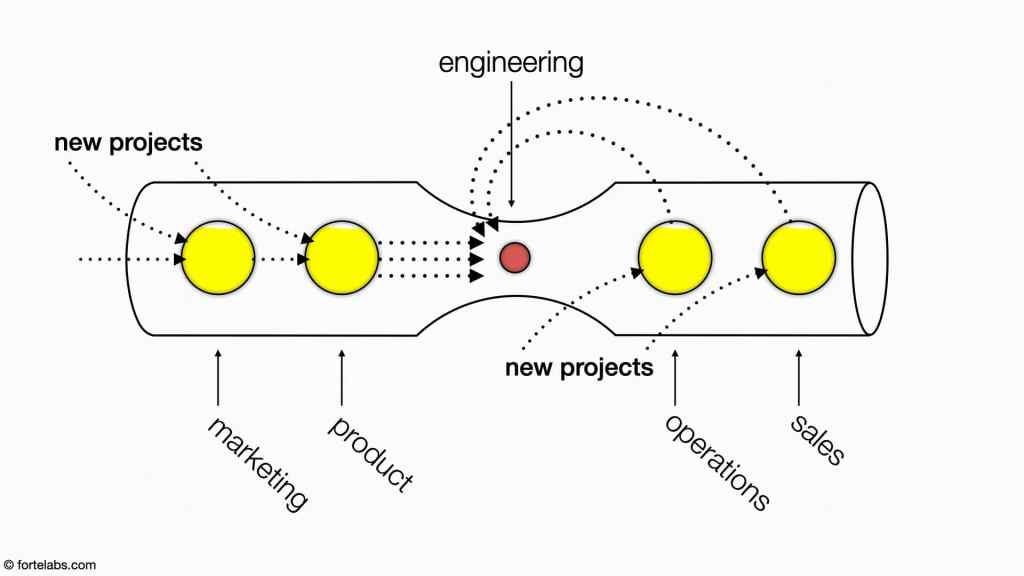

This wouldn’t be a problem if the departments worked completely independently of each other, but of course they don’t. As Sales, Product, and Design keep starting new projects, more work inevitably flows downstream to the already overburdened Engineering department:

Even if Engineering somehow has the discipline and authority to turn down all new requests, just deflecting the incoming communication takes up some of their precious capacity. It takes time and effort to manage more emails, provide more estimates, and perform the political maneuvering required to fend off the pressure from the rest of the business.

The consequence is that the bottleneck’s already strained capacity for productive work is even further reduced:

As the capacity of the bottleneck goes down, even more work piles up in front of it, which leaves upstream departments with even less to do, which causes them to start even more projects, which sends even more work down the pipe to the bottleneck, which reduces throughput even further.

Productivity dwindles to almost nothing as conflict, accusations, and political maneuvering to avoid blame all spiral out of control. But that’s not all.

The same situation is going on in the downstream departments: they find themselves waiting on work from the bottleneck, and to fill their own capacity in the meantime, they too start new projects. Once again, these departments are maximizing the use of their own capacity:

At least this downstream activity doesn’t affect the bottleneck, right? Wrong. These new projects also create more work for the bottleneck in the form of decisions that “require input from Engineering.” More phone calls, more emails, and more meetings – the bottleneck’s capacity for productive work is reduced even further:

At this point, with output drastically down, everyone angry with the bottleneck, the bottleneck resentful of everyone, and the bottom line suffering as no product is making it out the door, management feels the need to step in.

Because they don’t understand the principles at work, they start applying pressure. Everyone needs to work late, on weekends, eat lunch at their desks, and hit their targets! In other words, get even busier!

Because it is only the capacity of the bottleneck that makes a difference, all of this increased activity only makes the problem worse. All the departments send even more work to the bottleneck, which causes them to push back even harder, which causes everyone else to start new things in the meantime…

This is why a company where everyone is busy 100% of the time is terribly inefficient. The only way it’s possible for everyone to “stay busy” is for everyone to maximize their own productivity. And such individual optimization always comes at the expense of the company as a whole.

Trying to improve all parts of an organization is a worthy goal, but only improvement at the bottleneck will actually make a difference.

Follow us for the latest updates and insights around productivity and Building a Second Brain on Twitter, Facebook, Instagram, LinkedIn, and YouTube. And if you're ready to start building your Second Brain, get the book and learn the proven method to organize your digital life and unlock your creative potential.

- POSTED IN: Flow